Continuous Slot Well Screen

- Company ProfileBluslot filter

- Product BrandBluslot

- RegionChina

- CategoryEnvironment - Waste Management

- MashupChina Environment - China Waste Management

- RelatedJohnson Well Screen - Water Well Screen - Well Screen Pipe

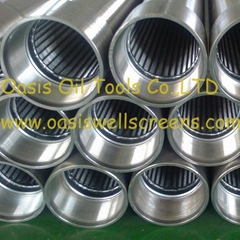

Water Well Screens consist of V-shape profile wire and the longitudinal support rods. theV wire is welded to the rods and produces a rigid unit that has high strength and minimum weight. so Water Well Screens has sturdy constriction and good mechanical property.

The V-shape section plane can avoid blockage and make sure of the unimpeded water. The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the Water Well Screens under the great pressure, so it can filter sand better. Meanwhile, the slot of Water Well Screens can change according to the real condition of the earth.

welded cylindrical screen

The construction correspond with the follow drawings respectively

1.Stangard contruction

2.Axial wire construction

3.Internal circumferential wire construction

4.inverwire construction

Advantages

Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

Long live: Welded at each intersection creating a strong and durable screen.

Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

- Contact Personkevin

- Telephone17772525335

- Fax Number

- Websitehttps://meshfiltro.com/

- Post Code053600

- AddressEconomic Development Zone, Hengshui City, Hebei Province, China.

- Online MapBluslot filter Map & Directions

Water Well Continuous Slot Screen

Continuous Slot Water Well Screen to play online casinos with free money, which also named above. “Free money” bonuses simply mean that they offer a certain amount Continuous Slot Water Well Screen of money to register a new game account as € 50 or € 100. A wide selection of precision-machined factory slot designs (.010'.125') with closely spaced inlet openings provides for uniform development over the length of the screen and proper stabilization of the gravel pack. Long Life Well rehabilitation costs are minimized, as PVC screens are inherently more.

Continuous Slot Johnson Screens is manufactured with V-shaped profile wire which is spirally wound around a cage of longitudinal support rods. Each intersecting point of these wires is fusion welded. The pitch of winding gives different spacing between two adjacent turns of wire. This spacing gives passage for water to enter. Wire wrapped screens are typically placed around gravel which separates the screen and the formation. They are widely used in oil field operations and water wells for lowest cost, keystone slots and high manufacturing efficiency. Wire wrapped screen features continuous slot which maximize the.

- SellOffer household food waste disposer

- SellTransformer Oil Filtration Processing Machine

- SellTransformer Oil Purification Degasification System

- SellTransformer Oil Filtration Processing Machine

- SellUsed Hydraulic Oil Purification Treatment Plant

- Sellvacuum insulating oil recycling

- SellTransformer Oil Filtration Processing

- SellEngine oil recycling

- SellJZS Engine oil recycling system

- SellSeries JZS Engine oil recycling system

- SellSeries JZS Engine oil recycling system

- SellSeries ZYD Double-stage vacuum transformer oil recycling

Continuous Slot Well Screens

The production of these Johnson screens type is by now consolidated, actually it has been produced since 1990 and it was preceded by 'Anti-sand' screen, which was manufactured with an inside simple screen and produced for about a decade.

Thanks to the experience and to the advanced technological machineries, nowadays it is possible to manufacture water screen with diameters from 60 to 1000 mm and with lengths up

to 12 metres.

It is the Johnson screen type that through the past years has been employed more and more, just for its excellent technical features.

The water screen, manufactured with a trapezoidal / triangular section of the spiral wrapped wire on loading rods according to the generators of a cylinder, can have slots from 0,20 mm onwards, so as to satisfy every request and every projecting need or of installation.

As already known, spiral screen for water well, like Johnson type screens, have, with equal diameter and slot, bigger opening surfaces than the ones of other kinds of screens (bridge or simple slot screen).

The higher percentage of opened area enlarges the profit of water. In Johnson screens type, the wide opened area simplifies enormously (in comparison with other screens) the washing of the well when, for instance, it is necessary to eliminate the mud panel.

In favour of the spiral Johnson type screens there is the chance to have smaller slots than the ones of other kinds of screen.

This is a great advantage when you have to filter waters in slimy soils where it is therefore necessary that the drain is of a very low grain size and that, at the same time, it cannot pass through the screen for water well itself.

Moreover, in rotation perched wells by inverted circulation, if the hollow space hole/casing is very small and such not to allow the forming of artificial drains,

it is better to employ these Johnson type screens with slots of 0,20 mm.